Grow with confidence

A turn-key solution for job shop manufacturing

Real-Time Production Traceability

Complete production traceability in Real-time to every step of the manufacturing process. Track & Trace lots, serial numbers, measurements, alarms & downtimes, who and when an action happened.

With a glimpse of an eye, you can track the completion of your production orders and your available resources.

The seamless traceability has a strong impact on the organization in total. Not only the production manager benefits from it, but also multiple levels such as customer relationship, sales, or ordering managers that can answer instantly customer’s questions, provide accurate delivery times, and be agile.

Also, tracking is attributed in terms of time, where you can easily access fast & slow production times, downtimes, and alarm duration. Moreover, important information about material consumptions, lot numbers, batches, suppliers, or even comments and images from operators are included.

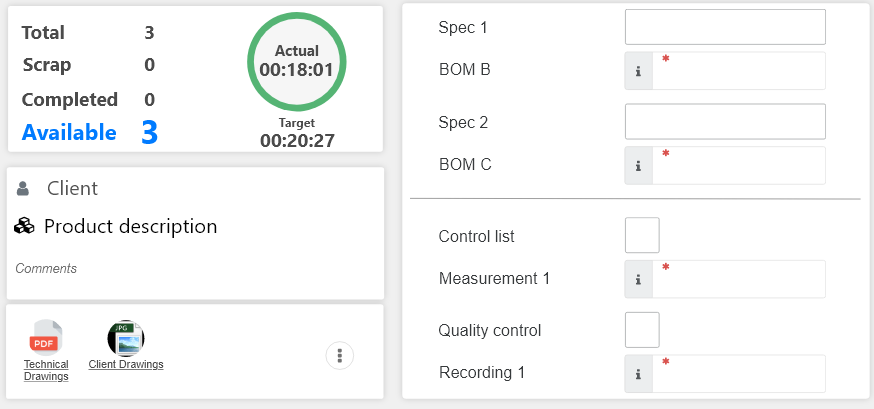

Execution

Provide complete and comprehensive work instructions in the most user-friendly software for operators. Instructions include drawings, specs, comments, and automation. Operators know exactly their workload and what to do next minimizing mistakes and overtime.

Along with document hosting per work order, contribute’s to an efficient production process & enormous cost reduction.

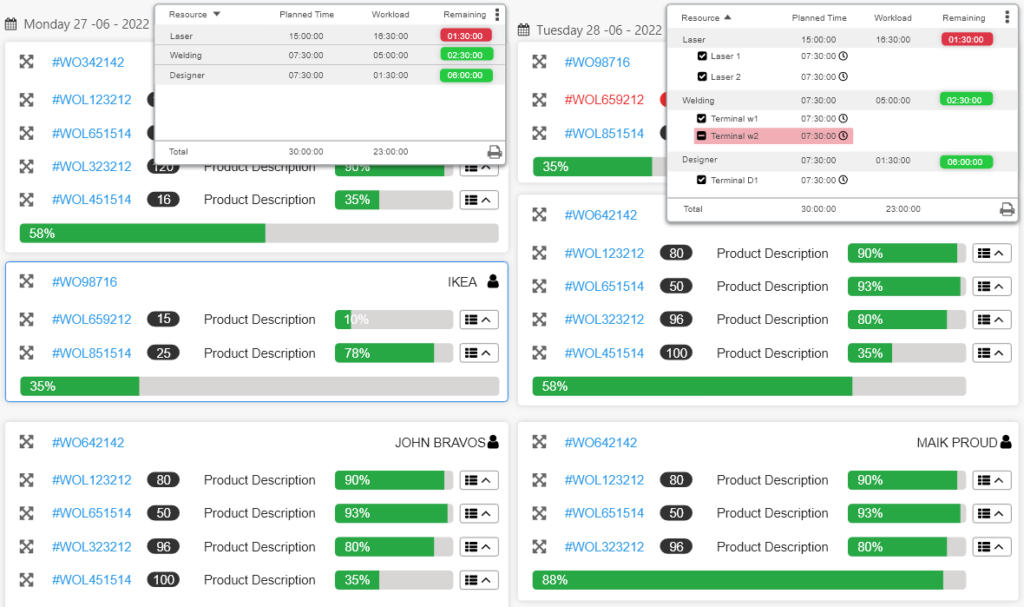

Advanced Scheduling

Epoptia utilizes your resources for the minimum availability loss depending on a target day, material throughput, and the availability of the previous production stages. It is a proven tool that reduces dramatically lead times, utilizes resources to a higher level, and improves deliverability.

With Drag&Drop, you can Re-Schedule your production orders and the system will provide delivery estimation upon your actions.

Urgent orders can be easily inserted and scheduled, with instant distribution on the shop floor.

Depending on the workload and actual situation of the production, indications are displayed to inform you about overload resources, alarms, and downtimes.

2-Way ERP Integration

With the use of our API, integrations are easy and flexible.

As far as ERP is concerned. There is two-way communication capability. Send every necessary information concerning your production orders, let Epoptia collect production information such as actual consumptions, users, implementation times, and send them back to your ERP or WMS using Webhook technology.

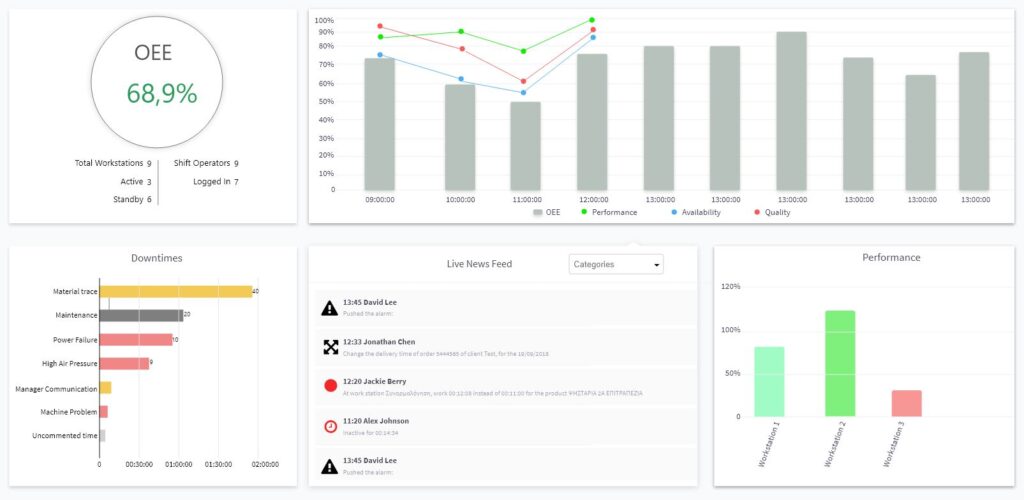

Dashboards

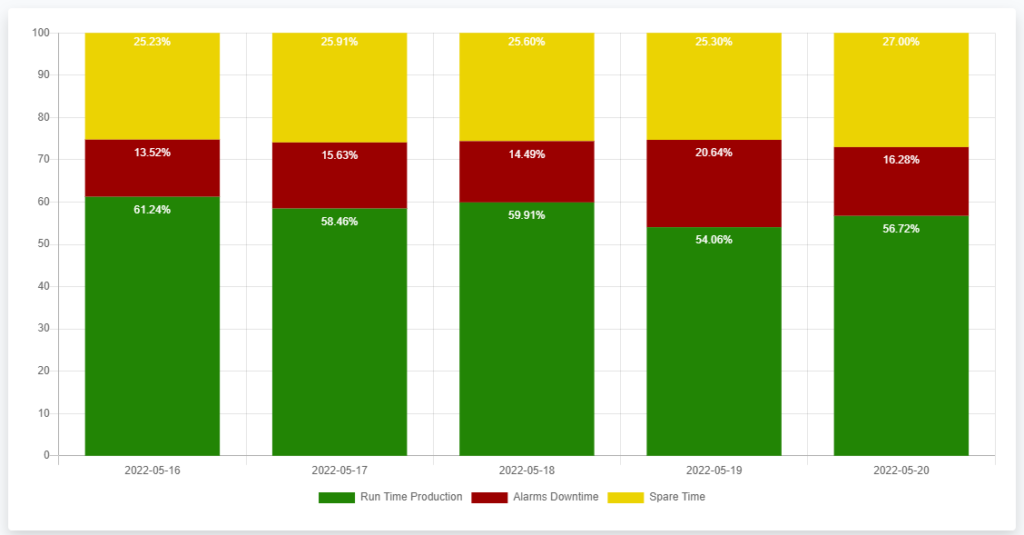

Meaningful dashboards visualize the plant’s actual situation for fast reaction times, decision-making support, and control of every resource.

Epoptia Dashboards are comprehensive showing live efficiency, time usage, downtimes, and other meaningful production insights.

Detect bottlenecks, and excessive workload and distribute your resources according to your needs.

Special & Custom dashboarding is provided for Private server installations.

Smart Workflows

Automate your production process with our interactive workflows. Set up the production cycle of your products by choosing from which workstations your products will pass through, with simple drag & drops.

Set technical documents, notes, and specifications to your products and workstations instantly and without the need for physical presence in every order.

Increase your productivity by categorizing your products according to specific workflows. Set rules for production and utilize our smart tools for automatic workflow synchronization.

Business Intelligence

Make use of our Machine Learning algorithms for delivery estimation.

Track your efficiency with Real-Time KPI’s and a complete Reporting suite. Make improvements and measure the impact, discover real problems, and record alarms & downtimes.

Become data-driven and ensure continuous flow.

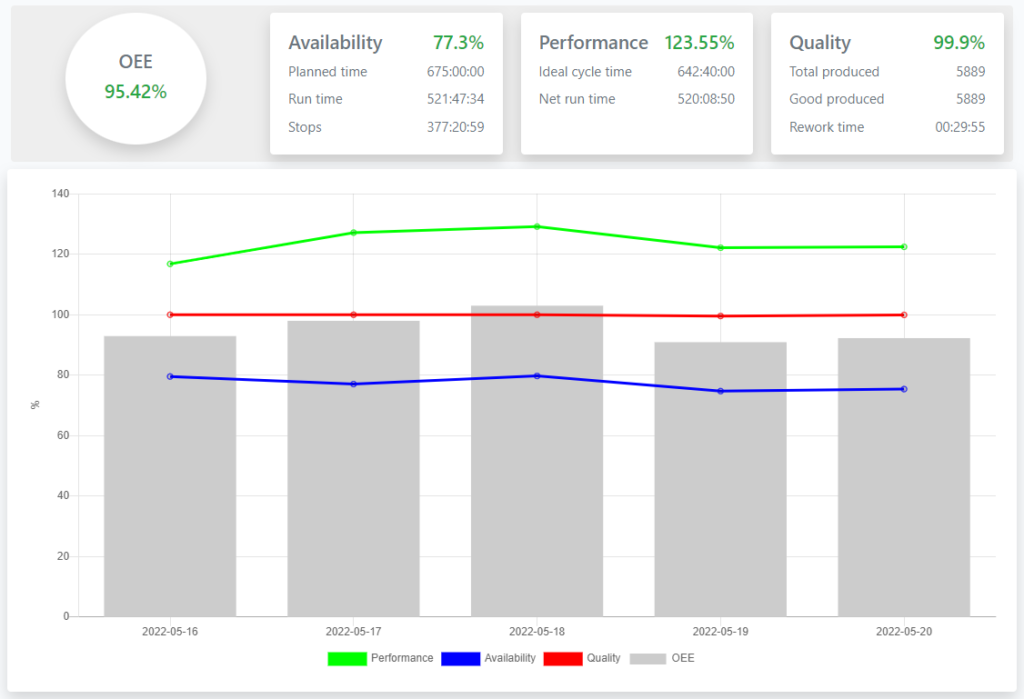

Overall Equipment Effectiveness is the main Key Performance Indicator provided by Epoptia MES.

Is the gold standard for measuring manufacturing productivity taking Availability, Performance & Quality into consideration.

The integrated reporting system provides analytical historical reports about Factory efficiency, time usage, alarms & downtimes, production quantities, product cycle times, workstations, and operators with compare capabilities. (Export to excel sheets is supported)

For our respective “On-Premise” clients, custom-made reports can be created.

IoT Integration

Connect your machines and record real start, stops, alarms and downtimes.

Collect measurements from instruments, sensors, and PLCs that are valuable to you and be sustainable with proof of manufacturing.

Combine production orders, operators, and IoT for your quality assurance policy and attract more clients.

IoT integration is made via advanced API

Capacity Planning

Resource utilization depending on priorities and availabilities are a core function of the platform, providing “lean manufacturing” attributes from the first day.

Insert your nominal times and see the capacity of every resource.

Change capacity based on actual needs and utilize your resources to the maximum

Take advantage of our Machine Learning algorithms and let Epoptia provide you with actual times per product and category.

Machine Learning to Production Targets

We are “Smart” because we are trained by your production.

We not only use this “mentality” in statistical reports but we also provide a unique feature.

With advanced machine learning algorithms, we calculate the actual cycle times of your products and provide them back to the workstations as a target, boosting productivity.

Of course, you can insert your own nominal cycle times.

Quality Assurance & Audit Preparation

Every step, action, and measurement is recorded, providing quality assurance and transparency.

As far as production procedures, you will be ready for ISO Certifications and Client Audits.

Print your labels and Quality Control forms automatically without manual entry.

Historical data are not only used for productivity analysis but also as proof of manufacturing and logs.

If a client makes a claim you can get back to your historicals and track exactly what happened in your production.