If you seek to establish a seamless workflow in your manufacturing enterprise, capacity planning is a vital step towards achieving it. Even though it can be performed manually, this method is prone to errors and does not provide the benefits that a system does. With capacity planning tools and a software, like Epoptia MES, you can plan, and measure your resource utilization, resulting in understanding your capacity capability and a way to optimize resource utilization. That means:

- Eliminating bottlenecks from the production process

- Increasing your capacity utilization and scheduling accuracy, or even

- Staying agile and consistent to sudden schedule changes

What is capacity planning

Capacity planning takes into consideration the resources of your plant such as machines, operators, available hours or even shifts, what products need to be produced and finally, overall efficiency. By considering all these factors, you can know whether you have the required capacity to meet customer demand. If capacity planning is done properly, managers can proactively add or subtract resources to meet commitments and give accurate delivery date estimations to their customers.

A capacity planning software allows you to see your future resource needs and allocate resources at the right time. For instance, say you are a manufacturing enterprise and you experience a sudden rise in demand. It will help you understand the actual production capacity needed to address any fluctuating demands for your products and services.

Epoptia capacity planning in action

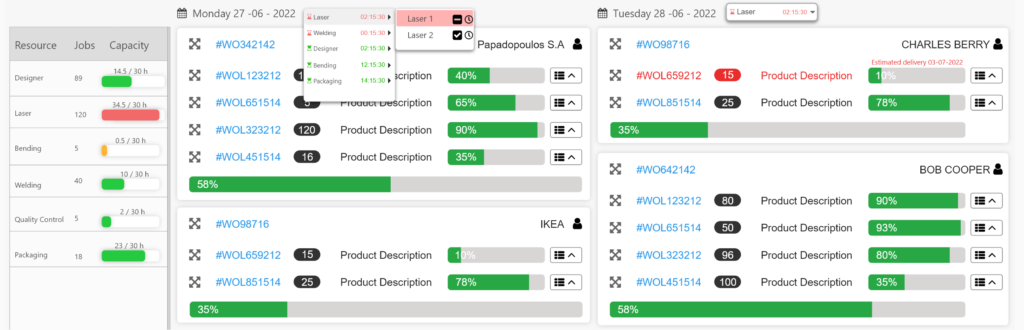

More specifically, Epoptia knows exactly which resources and routes are needed to complete a manufacturing order along with the time needed for each resource. Then, by providing how much time is available per resource, you can easily see if your schedule is on time or not and allocate your resources in the most efficient way possible. For example, by a simple drag and drop, you can change priorities and see the impact in your schedule, or increase a resource availability in order to know the exact manhours needed a certain workstation that needs more ‘’hands’’ to complete its job. In this way, you eliminate all idle times and urge your production to deliver on time.

Furthermore, since our features constantly get upgraded, really soon you will even have the option to leave it all to our AI which will have the ability to comb through and extract insights from all data much more quickly than a human planner could possibly manage.

Epoptia’s Capacity planning will respond directly to the following needs:

- Display of time workload per resource in total and per day.

- Dynamically changing resource availability per day for accurate calculations of manpower needs.

- Bottleneck detection and instant visualization of on time schedule.

- Delivery time estimation compared to the desired time with capability of sending it back to ERPs.

Benefits of a capacity planning software

With a capacity software, like Epoptia, you can know, plan, and measure your capacity utilization all in one place and get the following much desired benefits.

Get an accurate overview of your capacity anytime. At any given time, you can check the Gantt charts of operations per workstation to diagnose issues, identify bottlenecks and take steps to mitigate them before occurring. Moreover, you can outline your capacity by simply defining your workstations and organizing them into groups, based on their productivity, working hours, and planned downtime.

By using automated algorithms, you can accurately schedule all your production operations. That means that all tasks will be performed at the right time and place, as well as in the right quantity. In this way, you will be able to easily detect and resolve scheduling conflicts or avoid them in the future. Also, you can reschedule to quickly make changes in the production schedule when a disruption occurs or when order priorities shift.

Ultimately, you are able to see your capacity trends and effectiveness gradually improve. Historical data can help you identify seasonal trends and other recurring fluctuations in demand to adjust your production capacity as needed and in a timely manner. You can work towards your commitment to continuous improvement by monitoring manufacturing KPIs such as Overall Equipment Effectiveness (OEE) and adjust the processes.

All in all, a capacity planning software is a staple tool for project managers today since it makes a difference to the ease and efficiency of project planning.