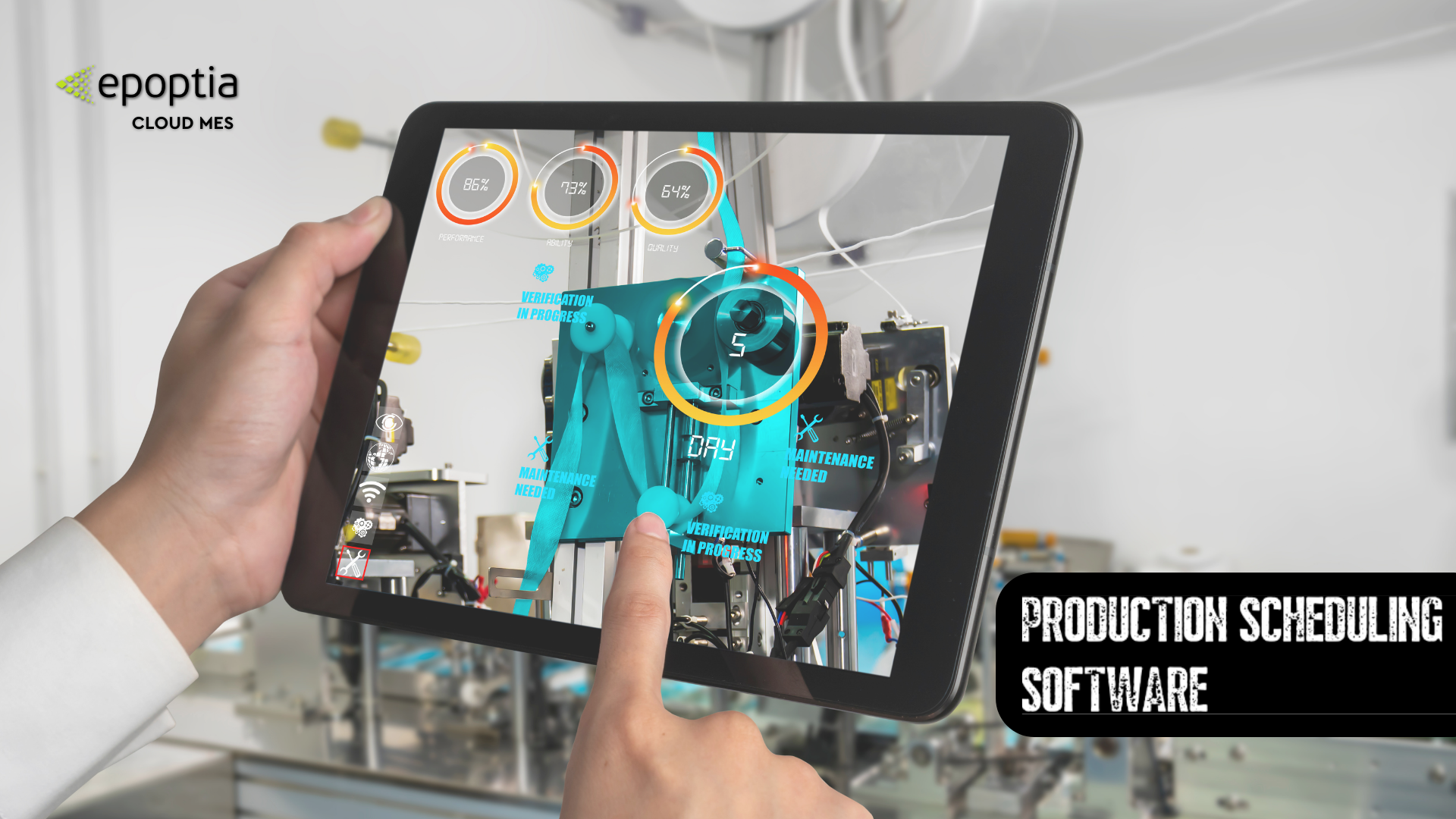

Learn about manufacturing execution software, a scheduling tool for job shop manufacturing, and how you can increase traceability and shorten lead times

A production scheduling software helps manufacturers keep track of their production at all times. This software applies both to discrete manufacturing operations and to continuous processes. By having such a powerful tool, they can make informed decisions regarding both short-term and day-to-day production operations. In other words, such a manufacturing execution software makes production planning easy and brings great benefits for the businesses that implement it. On top of our list, we have the increased traceability it offers and the shortened lead times.

What is a scheduling software?

We all know that managing your production operations can be a demanding and time-consuming process. Especially if you have to use spreadsheets to do so! Undoubtedly, the human factor is prone to errors from time to time and thus, affecting your whole production and keeping your business from thriving. That’s when a production scheduling software comes to the save. A production scheduling software helps you manage your manufacturing processes and capacity planning across your supply chain. Obviously, that can provide a range of benefits for your business since even the most complex process can now become a piece of cake. Production scheduling software may be employed on its own but oftentimes is paired with production planning software. Production planning software can be used to perform long and mid-term planning for your manufacturing business.

How does production scheduling software work? It uses advanced math to analyze and calculate optimal production schedules. To do so, it needs to consider a wide range of constraints based on a manufacturing company’s rules. Then, it sets-up a model about the resources needed to meet scheduling demands. That could be operators, machines, raw materials, the supplies needed, and more. More specifically, a production scheduling software pertains to:

- Creating order-based multi-constraint scheduling to prioritize orders

- Employing schedule optimization rules to solve problems that may arise such as minimizing changeover times or implementing preferred sequencing

- Implementing custom rules about material allocation and consumption

- Modeling of advanced resource constraints (such as, limit the time between operations)

What are the benefits?

Production scheduling software includes graphical representations (visual scheduling on the Gantt, as well as grid-like views) that help managers to visualize assembly processes from raw materials to finished goods. Moreover, a production scheduling software offers schedule visibility for all of the manufacturing business departments. That is, they can view and edit information when needed. This has a great deal of benefits for various departments. The sales department can easily track order progress. The management team can seamlessly assess actual versus scheduled completion times. Finally, operators have the ability to view up-to-the-minute work orders generated by the production scheduling system.

Apart from full visibility, a production scheduling software brings multiple advantages for job shop manufacturing in regards of lead times and traceability. These include:

- Shorter Lead Times. With a production scheduling software, your schedule is automatically generated based on customer orders and demand forecasts. It will schedule your jobs automatically with no further effort. In this way, managers can save a significant amount of time. For instance, when there is a demand change, they can quickly adjust and optimize the schedule to maximize the throughput of the facility and meet customer demands. Apart from this, a production scheduling software allows them to plan weeks or even months in advance based on customer demand. This ensures that the job shop is able to produce and deliver products on time.

- Increased Traceability. With a production scheduling software, your production scheduling is immediately simplified. You can track and trace products in your supply chain from production to the end customer. For example, with QR codes and RFID scans to products and boxes. This means real-time tracking for the entire production process to identify bottlenecks, unnecessary delays and unexpected costs. Also, since a scheduling software has the the ability to offer full visibility to your shop floor, information is instantly available for every department. With features such as timeline views and due date notifications, everyone can help improve production efficiency and product quality.

Conclusion

Ultimately, manufacturers can employ said software on its own. Thus, oftentimes it is paired with production planning software. Production planning software can be used to perform long and mid-term planning for your manufacturing business. In modern manufacturing operations, we usually employ both software as part of an advanced planning and scheduling (APS) software system. With a cloud manufacturing software, like Epoptia MES, you can take your business to the next level!

Is your job shop manufacturing business in need of a full solution regarding production planning and scheduling? Do you wish to try out a manufacturing execution software to see its benefits in increasing productivity and efficiency?For more information, check https://bit.ly/3vYnb4f.