Industrial IoT

An important element of Industry 4.0, an asset for Epoptia

Internet of Things (IoT) constitutes an important element of Industry 4.0 and it can undoubtedly change the way industries have been working so far. But what does it refer to? A simple way of viewing IoT is as a novel and disruptive concept that is based on connecting our entire surrounding environment automatically, without needing human interaction. Thanks to IoT industries have been reinventing themselves all around the globe. Human error has been reduced at a substantial degree and that, along with better and more suited identification of potential issues, has greatly increased quality.

Epoptia is highly invested in IoT and strives to never cease evolving and keeping up with the latest advancements in the field. For example, we ensure each product’s quality by connecting instruments and other external quality measurements to Epoptia cloud Manufacturing Execution System (MES). For every product, measurements can be controlled using special functions, triggering alarms when needed and they can also be recorded to work orders, for quality and archival purposes.

Why do we need Industrial IoT?

For the most part, IIoT facilitates daily prompt and accurate communication between machines. The fact that everything is connected digitally without any human interaction leads to great automation, which in turn offers faster and efficient outcomes. There is full transparency among the various processes and hence the quality of the products or services is assured. That also saves time and in many industries time is money. The financial gains however are not only limited to the amount of time that is being saved with use of IoT. As a result of bidirectional communication, total integration and high automation, we can now detect issues faster and collect information about downtimes, breakdowns and damages to the system.

Needless to say, by gathering real-time data we can reap the benefits of seamless production traceability. For instance, just imagine how knowing the completion percentage for each product at any given time can increase productivity. Additionally, we can make the most of our production by changing order priority throughout the day and between days as well.

Another noteworthy advantage that we get from IIoT is the dissemination of information which is performed instantaneously and flawlessly. In that way, every party involved has access to the pieces of information they need to better perform their tasks. Information is power and with IIoT that power is attainable by the industry’s personnel on any occasion.

Last but not least, Industrial IoT can provide real proof of manufacturing and save tons of printed papers at the same time. How is that possible? All actions, measurements, or controls are stored inside a cloud MES. Then, a Data Matrix code is automatically generated and printed on the labels that are attached to each product. Once the Data Matrix is scanned by any device, it leads to a single page website with the product’s information, certifications, manuals, etc.

What can you do with Epoptia?

Basically, you can collect data from everywhere.

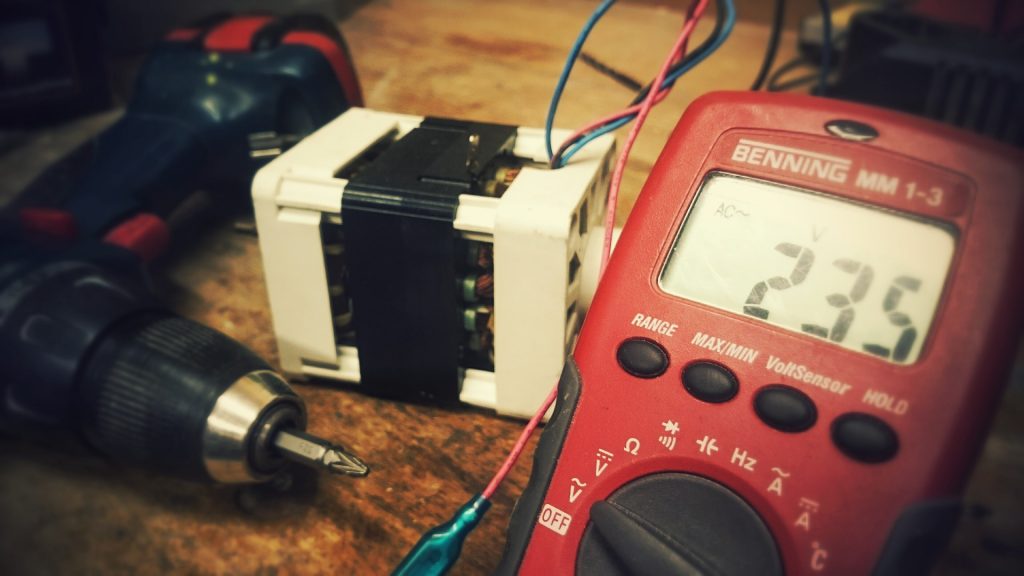

With Epoptia you can connect various machines and instruments such as: Sensors, Measuring instruments (scales or voltage/current measuring instruments), Alarms directly from the machines, Production rate & quantity and Counters. In other words, we collect data from everywhere!

Employees: Epoptia is optimized to collect information from employees and it is engineered with their contribution which is the KEY to a successful operation.

PLC – Machines: We collect information that matters to you and your costs like productivity information, alarms and downtimes directly from your machines.

Sensors: With our API you can collect production insights that you want to track, send warnings if something is detected or control a state. Imagination is the frontier.

Instruments: You can collect, control and inspect online quality information for your products. If out of specs, activate alarms. Measure and record valuable measurements for your productions insight.

How does Epoptia use Industrial IoT?

Epoptia uses an Application Programming Interface (API) where anyone can send values to Epoptia through our documentation. The advantages of using an API are several and the most obvious one is the automatization that is achieved through it. Employees perform fewer tasks on the platform since most of them are already programmed and executed by a mainframe and that increases efficiency and productivity by allowing them to streamline their operations with fewer complications. What is more, it is overly uncomplicated for them to implement new functions and tailor it according to their needs without any expertize or advanced technical skills. That clearly offers a tremendous flexibility to a business.

To better illustrate this let’s go through an indicative function that can be performed with the help of an API. Say that an employee needs to perform some tasks regarding power supply in wiring. He can check the tasks he performed and then simply by drawing information from measuring instruments the API can indicate whether voltage and current values are within acceptable limits and if not he can trigger an alarm and resolve the issue. Additionally, all employees’ actions are being recorded on the platform and managers can check their detailed history, as well as their overall productivity within the time period of their choice.