Learn about eliminating bottlenecks and increase the overall efficiency of your manufacturing business

Manufacturing is a complex process that involves various stages and processes. From sourcing raw materials to delivering finished products, every step is critical for the success of a manufacturing business. Nonetheless, even the most optimized processes can still face challenges and one of the most common problems is bottlenecks. In this guide, we’ll discuss what bottlenecks are, how to find them and most importantly, how to eliminate them to increase the overall efficiency of your manufacturing business.

What is a bottleneck in manufacturing?

A bottleneck is a stage in a manufacturing process where production is slowed down or halted due to a lack of resources, such as labor, equipment, or materials. For instance, this can occur when one machine or worker in the production process is slower or less efficient than the others. As a result, the other machines or workers have to slow down or stop to wait for the slowest machine or worker to catch up.

The bottleneck stage limits the overall capacity of the manufacturing process and can cause delays, increased production costs and missed deadlines. Thus, identifying and addressing bottlenecks is crucial for ensuring the smooth flow of production and maximizing the efficiency of your manufacturing business.

How to identify bottlenecks in your manufacturing process

To begin with, identifying bottlenecks in your manufacturing process can be challenging, but it’s essential to maximize efficiency and productivity. It is the first step towards eliminating them. Some common indicators that can help you identify them are long wait times between processes, frequent machine breakdowns and maintenance issues, or even high levels of scrap and rework. Here are some steps you can take to find these bottlenecks in your manufacturing process:

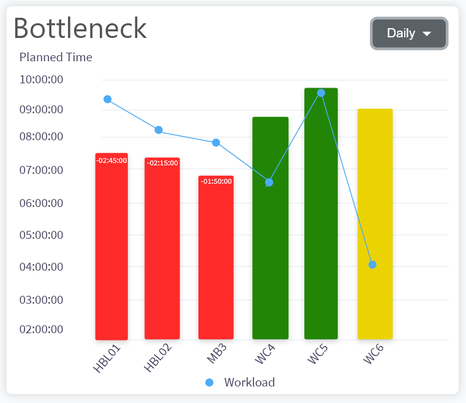

1. Analyze your production data: Collect and analyze data on the production process to identify patterns and trends. Use tools such as machine sensors, production monitoring systems, and workflow management software to capture data and identify bottlenecks.

2. Map your production process: Create a visual representation of your production process to identify stages that are causing delays or inefficiencies. Use process flow diagrams, value stream mapping, or other visualization techniques to map your production process.

3. Conduct a capacity analysis: Determine the maximum capacity of each stage of your production process and compare it to the actual output. Identify stages that are operating below capacity and investigate the root cause

How to eliminate bottlenecks in your manufacturing process

Eliminating bottlenecks is crucial for increasing the efficiency of your manufacturing process. Here are some strategies to consider:

1. Redesign the production process: After identifying bottlenecks, consider redesigning the production process to eliminate the bottleneck stage. This could involve rearranging the production line, increasing the capacity of equipment or hiring additional staff.

2. Implement automation: Automating repetitive or manual tasks can help to reduce bottlenecks and increase production efficiency. Consider implementing robotics, machine learning, or other automation technologies to improve the efficiency of your manufacturing process.

3. Train employees: Provide training and support to employees to improve their skills and increase their productivity. This can help to reduce bottlenecks caused by human error or inefficiencies

How Epoptia Can Help

Epoptia is a powerful cloud-based manufacturing execution system that offers real-time monitoring and reporting capabilities. This helps manufacturers identify and eliminate bottlenecks in their production process quickly. With its advanced technology, it can collect and analyze production data, map the production process and conduct capacity analysis to identify areas that are causing delays or inefficiencies.

Epoptia can help you redesign your production process, automate repetitive or manual tasks and train your employees to improve their skills and increase their productivity. The real-time monitoring and reporting features allow you to make informed decisions quickly. In this way, you can optimize your production process and increase the overall efficiency of your manufacturing business.

What sets Epoptia apart is its ability to provide valuable insights into your production processes. This helps you make informed decisions to optimize efficiency. With just a blink of an eye, you can access all the information you need. In this way, you can identify and eliminate bottlenecks, ultimately improving your manufacturing process and increasing your bottom line.

If you’re struggling with bottlenecks in your manufacturing process and looking for a solution to help optimize efficiency, contact us today to schedule a presentation.

For more information, check https://bit.ly/3vYnb4f.