Discover how job shops can regain control of delivery performance with real-time visibility

To begin with, in custom manufacturing, on-time delivery can make or break client relationships. Yet, despite everyone’s best efforts, many job shops still face delayed deliveries, rising overtime costs, and unhappy customers. Despite solid planning, skilled teams, and well-maintained machines, orders still slip.

So, why do delayed deliveries in manufacturing happen so often? The truth is, it’s rarely a single big mistake. Instead, it’s the accumulation of small inefficiencies (missing data, late updates, or a lack of real-time insight) that quietly disrupt the entire production flow.

Drawing on insights from Epoptia’s 100+ MES installations across the world, this article breaks down the 3 main root causes of late deliveries and shows how an MES system reduces lead time and boosts delivery reliability for job shops and custom manufacturers alike.

1. Poor Scheduling Visibility

First and foremost, the biggest enemy of on-time delivery is often outdated scheduling data. Many job shop manufacturers still rely on spreadsheets or whiteboards to manage complex orders. While these tools might work at the start of the day, they quickly fall out of sync once real-life events hit the shop floor.

A late material delivery, a rework request, or an urgent new job can throw the entire schedule off balance. Without a live view of production, managers are left guessing which orders are in progress, which are delayed, and which need attention first.

As one Epoptia client in sheet metal fabrication put it:

“Our planning used to look perfect at 8 a.m., and completely wrong by noon.”

This lack of transparency creates confusion and wastes time. That is, supervisors run from one workstation to another asking for updates, while operators lose focus waiting for new instructions. The end result? Missed deadlines and frustrated customers.

How Epoptia MES Fixes It: Real-Time Scheduling Visibility

Epoptia MES replaces static planning with dynamic, real-time scheduling. Each job’s progress, operator status, and machine activity are updated automatically as work happens. When a task takes longer than planned, the system immediately adjusts the next jobs and highlights potential delivery risks.

This means planners no longer react to problems after they occur, they anticipate them before they affect deadlines. The result is smoother production flow, faster decision-making, and a clear overview of your entire factory at any given moment.

2. Unexpected Machine Downtime

Secondly, another major cause of delayed deliveries in manufacturing is unplanned machine downtime. Even a few unexpected hours can disrupt tightly packed production schedules. In job shops, where lead times are short and order mixes change daily, a single breakdown can affect multiple customer orders.

Unfortunately, many manufacturers don’t realize how much downtime is truly costing them, mainly because it isn’t tracked in real time. Maintenance teams often find out long after a machine has stopped, losing valuable recovery time.

One precision machining company using Epoptia discovered that hidden downtime was eating up nearly 18% of their available production time. Once they began monitoring it through MES, they reduced downtime by 30% within the first months.

How Epoptia MES Fixes It: Live Downtime Tracking and Alerts

With Epoptia MES, operators can log downtime events directly from their workstation with a single click. They simply select the reason (such as machine failure, tooling change, or material shortage) and the system automatically records the duration.

Supervisors receive instant alerts about critical stoppages, enabling maintenance teams to act immediately instead of hours later. Over time, this data helps uncover recurring issues and supports preventive maintenance strategies.

By turning downtime data into actionable insights, manufacturers can reduce production lead time, avoid bottlenecks, and maintain their delivery promises.

3. Manual Data Collection Delays

Lastly, one of the most underestimated causes of on-time delivery problems is the use of manual reporting. Many job shops still rely on handwritten notes or Excel sheets filled in at the end of the shift. By the time the information reaches planners, it’s already outdated, and sometimes incomplete.

To make matters worse, manual data entry not only wastes time but also introduces errors. Operators forget exact times, omit minor stoppages, or round up numbers for convenience. The result is a distorted view of what really happened on the shop floor.

Before adopting Epoptia MES, a subcontracting workshop used to discover schedule deviations one or two days after they occurred. After switching to real-time data capture, they reduced average lead time by 14% and achieved far greater control over production.

How Epoptia MES Fixes It: Real-Time Data Capture and Transparency

Epoptia eliminates paper and manual inputs by enabling operators to record every job in real time through a simple digital interface. Each start, stop, or pause action is instantly logged in the cloud, giving supervisors a live picture of shop-floor performance.

Because everyone works from the same real-time data, communication improves dramatically. Production teams know exactly what to prioritize, planners see accurate progress updates, and managers can make informed decisions without delays. or data, job shops gain the confidence to commit to deadlines and the flexibility to adapt when reality changes.

From Data to Action: Solving the Real Root Causes of Delays

In a nutshell, while these three causes (poor scheduling visibility, downtime, and manual reporting) may seem separate, they’re deeply connected. Manual data creates blind spots. Those blind spots hide downtime. And hidden downtime leads to unreliable schedules.

By implementing Epoptia MES, job shops close these gaps and replace uncertainty with clarity. Production managers finally gain full control over what’s happening, minute by minute, across their facility. When visibility improves, downtime decreases, and data becomes real-time, on-time delivery performance naturally rises, along with customer satisfaction.

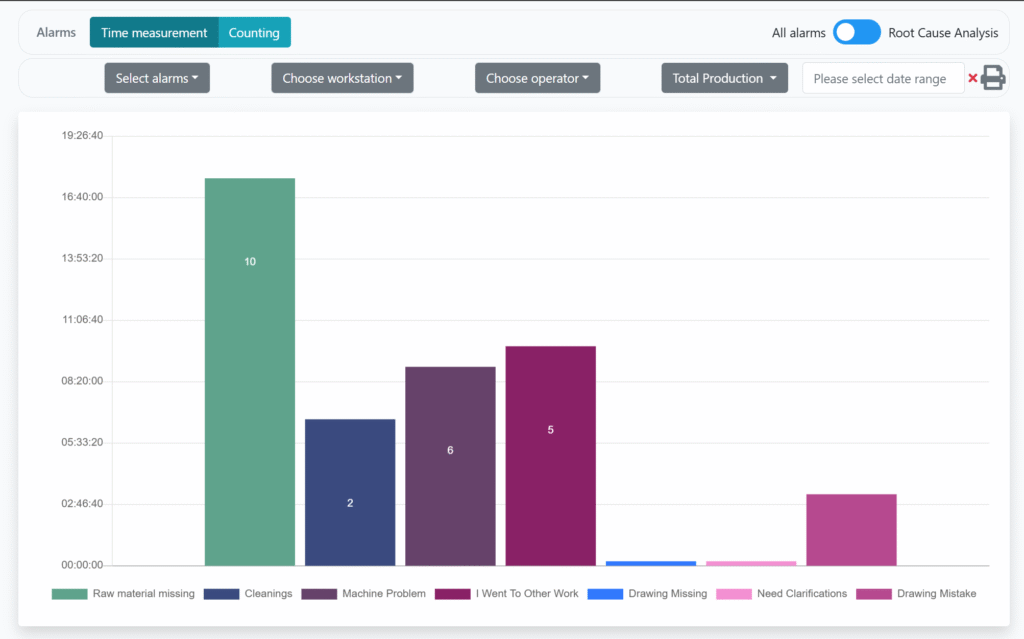

However, beyond visibility and tracking, Epoptia MES goes a step further, helping manufacturers truly understand why delays happen. Through its Alarms and Root Cause Analysis System, operators can log every issue directly from their workstation with just a few clicks. That is, from raw material missing, to machine problem, or drawing mistake, every cause of delay is recorded and time-stamped.

These real-time inputs are then automatically visualized in a Pareto Chart, giving production managers an instant overview of the top reasons behind lost time.

With this insight, factories can not only recognize and measure their main problems but also implement corrective actions and later measure the actual impact of those improvements.

This continuous improvement loop has already helped Epoptia clients worldwide uncover hidden inefficiencies, reduce delays, and boost productivity across departments.

By transforming daily feedback from operators into actionable data, Epoptia empowers manufacturers to move from firefighting to data-driven decision-making.

Conclusion

In conclusion, delayed deliveries don’t stem from bad planning, they stem from invisible inefficiencies that go unnoticed until it’s too late.

By tackling the three root causes with Epoptia MES, manufacturers gain the insight and agility they need to stay competitive. Real-time visibility, automated data collection, and proactive downtime management together ensure that every order moves on schedule, from the first operation to final shipment.

Epoptia helps job shops turn delivery promises into delivery performance, day after day.

Want to see how Epoptia MES can help your factory eliminate delays and achieve real-time control? Request a free presentation at https://epoptia.io/register.

For more information, visit https://epoptia.com.

The main reasons include poor visibility of production schedules, unplanned machine downtime, and manual reporting delays. These issues create gaps in communication that lead to missed deadlines.

MES software provides real-time data on job progress, downtime, and machine performance. This helps managers act immediately when delays occur, improving planning accuracy and reducing lead time.

Yes. Epoptia offers ready-made integrations with popular ERP systems like SAP and Odoo, ensuring a seamless data flow between planning and execution.