Μάθετε για την Ανάλυση Αιτίων, μια διαδικασία που χρησιμοποιείται για τον εντοπισμό των υποκείμενων αιτιών των προβλημάτων στην παραγωγή.

Στον ταχέως εξελισσόμενο και πολύπλοκο κόσμο της μεταποίησης, τα προβλήματα και οι προκλήσεις είναι αναπόφευκτα. Από τις καθυστερήσεις στην παραγωγή έως τα ζητήματα ποιότητας, τα προβλήματα αυτά μπορεί να έχουν σημαντικό αντίκτυπο στην παραγωγικότητα, την ικανοποίηση των πελατών και το τελικό αποτέλεσμα. Εδώ είναι που μπαίνει στο παιχνίδι η ανάλυση αιτιών (RCA). Η Ανάλυση Αιτίων είναι μια θεμελιώδης τεχνική επίλυσης προβλημάτων που χρησιμοποιείται στη μεταποίηση για τον εντοπισμό των υποκείμενων αιτιών των ζητημάτων ή των αποτυχιών. Επιπλέον, εμβαθύνοντας στα βαθύτερα αίτια, οι κατασκευαστές μπορούν να εφαρμόσουν αποτελεσματικές λύσεις που αντιμετωπίζουν τα βασικά προβλήματα, οδηγώντας σε βελτιωμένη παραγωγικότητα, ποιότητα και συνολική λειτουργική αποδοτικότητα.

Τι είναι η Ανάλυση Αιτίων;

Κυρίως, η Ανάλυση Αιτίων (RCA) είναι μια συστηματική προσέγγιση που αποσκοπεί στην αποκάλυψη των υποκείμενων αιτιών των προβλημάτων ή των περιστατικών και όχι στην αντιμετώπιση των συμπτωμάτων τους. Περιλαμβάνει μια δομημένη διαδικασία διερεύνησης που υπερβαίνει τις άμεσες εξηγήσεις και αναζητά τους θεμελιώδεις παράγοντες που συμβάλλουν σε ένα ζήτημα. Με τον εντοπισμό και την αντιμετώπιση των βαθύτερων αιτιών, οι κατασκευαστές μπορούν να αποτρέψουν την επανάληψη των προβλημάτων και να προωθήσουν τη μακροπρόθεσμη βελτίωση των διαδικασιών. Ακολουθούν τα βασικά βήματα που εμπλέκονται στην RCA:

1. Αναγνώριση του προβλήματος: Αναγνωρίζουν και αντιμετωπίζουν τις ανεπάρκειες ή τα ζητήματα της διαδικασίας παραγωγής ως ευκαιρίες βελτίωσης.

2. Ορισμός του προβλήματος: Καθορίστε με σαφήνεια το πρόβλημα ή το περιστατικό για να διασφαλίσετε την κοινή κατανόηση μεταξύ όλων των ενδιαφερομένων μερών.

3. Ανάλυση προβλήματος: Διεξάγετε ενδελεχή ανάλυση του προβλήματος, εξετάζοντας τα μοτίβα και τις περιοχές εμφάνισης.

4. Προσδιορισμός της αιτίας: Αναλύστε τις αιτιώδεις σχέσεις για να εντοπίσετε τον κύριο παράγοντα που συμβάλλει στο πρόβλημα.

5. Εξάλειψη αιτιών: Εφαρμόστε στοχευμένες δράσεις για την εξάλειψη ή τον μετριασμό της αιτίας.

6. Παρακολούθηση συμπτωμάτων: Συνεχής παρακολούθηση των δεικτών για να διασφαλιστεί η αποτελεσματικότητα των εφαρμοζόμενων λύσεων

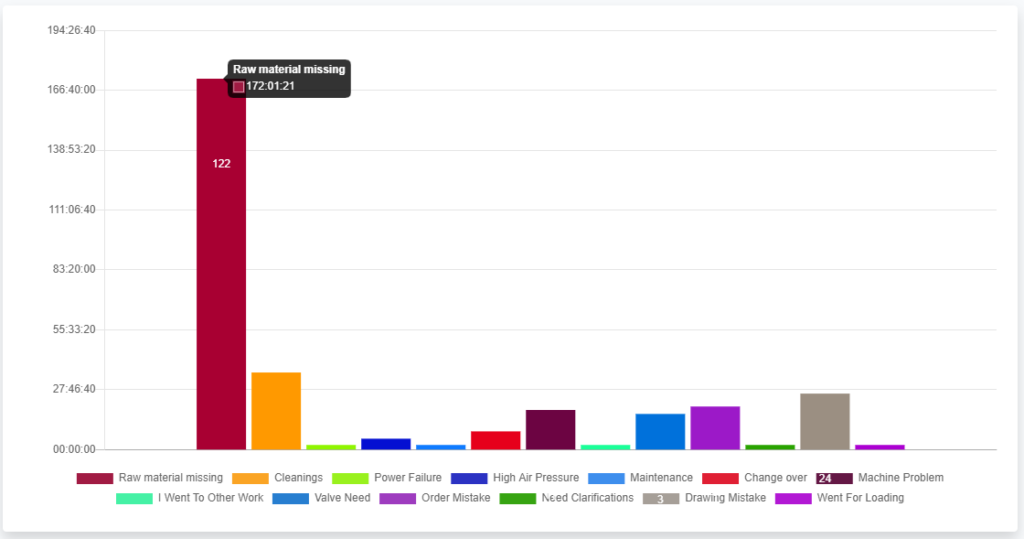

Εντοπισμός διακοπών λειτουργίας στην οθόνη Epoptia MES για την εφαρμογή ανάλυσης αιτιών

Μέθοδοι RCA στη μεταποίηση

Αναμφισβήτητα, όταν πρόκειται για τον εντοπισμό και την επίλυση προβλημάτων στη μεταποίηση, η εφαρμογή αποτελεσματικών μεθόδων ανάλυσης αιτιών είναι ζωτικής σημασίας για τη βιώσιμη βελτίωση και τη λειτουργική αριστεία.

1. Τα 5 γιατί: Αυτή η μέθοδος περιλαμβάνει την επανειλημμένη ερώτηση “γιατί” για να εμβαθύνει στις σχέσεις αιτίου-αποτελέσματος πίσω από ένα ζήτημα. Θέτοντας μια σειρά από ερωτήσεις “γιατί”, μπορείτε να αποκαλύψετε τις υποκείμενες αιτίες και να φτάσετε στη ρίζα του προβλήματος.

2. Διάγραμμα Fishbone (Διάγραμμα Ishikawa): Αυτό το οπτικό εργαλείο βοηθά στον εντοπισμό και την κατηγοριοποίηση των πιθανών αιτιών, οργανώνοντάς τες σε μεγάλες κατηγορίες, όπως οι άνθρωποι, η διαδικασία, ο εξοπλισμός, τα υλικά και το περιβάλλον. Το διάγραμμα ψαροκόκαλο παρέχει ένα δομημένο πλαίσιο για τον καταιγισμό ιδεών και την ανάλυση πιθανών αιτιών.

3. Διάγραμμα μήτρας: Το διάγραμμα μήτρας είναι ένα οπτικό εργαλείο που βοηθά στην ανάλυση των σχέσεων μεταξύ διαφορετικών παραγόντων και των επιπτώσεών τους σε ένα συγκεκριμένο ζήτημα. Σας επιτρέπει να αξιολογήσετε τη δύναμη και τη σημασία των διαφόρων παραγόντων και να εντοπίσετε τους παράγοντες με τη μεγαλύτερη επιρροή.

Οφέλη της RCA στη μεταποίηση

Ο εντοπισμός και η αντιμετώπιση των βαθύτερων αιτιών των προβλημάτων είναι ουσιώδους σημασίας για τη βελτίωση της αποδοτικότητας και της αποτελεσματικότητας των διαδικασιών παραγωγής. Η ανάλυση αιτιών παρέχει μια δομημένη προσέγγιση για την κατανόηση των υποκείμενων αιτιών των προβλημάτων και τη λήψη διορθωτικών μέτρων.

1. Ενισχυμένη επίλυση προβλημάτων: Η RCA βοηθά τους κατασκευαστές εργοστασίων να ξεπεράσουν την αντιμετώπιση των συμπτωμάτων και να επικεντρωθούν στον εντοπισμό και την επίλυση των υποκείμενων αιτιών. Αυτό οδηγεί σε αποτελεσματικότερη επίλυση προβλημάτων και αποτρέπει την επανάληψη προβλημάτων.

2. Βελτιωμένη αποδοτικότητα: Με την εξάλειψη των βαθύτερων αιτιών, οι κατασκευαστές μπορούν να εκσυγχρονίσουν τις διαδικασίες, να μειώσουν τη σπατάλη και να βελτιστοποιήσουν τη χρήση των πόρων. Αυτό οδηγεί σε βελτιωμένη παραγωγικότητα, μειωμένο χρόνο διακοπής λειτουργίας και αυξημένη λειτουργική αποδοτικότητα.

3. Βελτίωση της ποιότητας: Επίσης, η RCA επιτρέπει στους κατασκευαστές να εντοπίζουν τις βασικές αιτίες των προβλημάτων ποιότητας, όπως ελαττώματα ή αποκλίσεις από τις προδιαγραφές. Με την αντιμετώπιση αυτών των αιτιών, οι κατασκευαστές μπορούν να βελτιώσουν την ποιότητα των προϊόντων, να μειώσουν την επανεπεξεργασία ή τα απορρίμματα και να αυξήσουν την ικανοποίηση των πελατών.

4. Μείωση του κόστους: Ο εντοπισμός και η εξάλειψη των βαθύτερων αιτιών της αναποτελεσματικότητας μπορεί να οδηγήσει σε σημαντική εξοικονόμηση κόστους. Με την αντιμετώπιση των υποκείμενων ζητημάτων, οι κατασκευαστές μπορούν να μειώσουν τις καθυστερήσεις στην παραγωγή, να ελαχιστοποιήσουν τη σπατάλη υλικών και να βελτιστοποιήσουν την κατανομή των πόρων, οδηγώντας σε μείωση του κόστους σε όλους τους τομείς.

5. Συνεχής βελτίωση: Η RCA προωθεί μια κουλτούρα συνεχούς βελτίωσης εντός του οργανισμού παραγωγής. Έτσι, με τη συνεπή ανάλυση των βαθύτερων αιτιών και την εφαρμογή διορθωτικών ενεργειών, οι κατασκευαστές μπορούν να προωθήσουν συνεχείς βελτιώσεις στις διαδικασίες, τα προϊόντα και τη συνολική επιχειρησιακή απόδοση.

6. Λήψη αποφάσεων με βάση τα δεδομένα: Η RCA βασίζεται στην ανάλυση δεδομένων και στη λήψη αποφάσεων βάσει στοιχείων. Συλλέγοντας και αναλύοντας τα σχετικά δεδομένα, οι κατασκευαστές μπορούν να αποκτήσουν πολύτιμες γνώσεις για τις δραστηριότητές τους, να εντοπίσουν τάσεις και να λάβουν τεκμηριωμένες αποφάσεις για τη βελτιστοποίηση των διαδικασιών.

Συμπέρασμα

Το Epoptia, ένα σύστημα εκτέλεσης παραγωγής που βασίζεται στο cloud, υποστηρίζει την εφαρμογή της ανάλυσης αιτιών, παρέχοντας δυνατότητες συλλογής, ανάλυσης και υποβολής εκθέσεων δεδομένων σε πραγματικό χρόνο. Με το Epoptia, οι κατασκευαστές μπορούν εύκολα να συλλέγουν και να αναλύουν δεδομένα από διάφορες πηγές, να συνεργάζονται για την επίλυση προβλημάτων και να παρακολουθούν την αποτελεσματικότητα των εφαρμοζόμενων λύσεων.

Ξεκλειδώστε τα οφέλη της ανάλυσης αιτιών στις διαδικασίες παραγωγής του εργοστασίου σας με το Epoptia MES. Επικοινωνήστε μαζί μας σήμερα για να μάθετε περισσότερα και να ξεκινήσετε το ταξίδι σας προς τη συνεχή βελτίωση και τη λειτουργική αριστεία.

Για περισσότερες πληροφορίες, δείτε https://bit.ly/3vYnb4f.