Μάθετε για την εξάλειψη των σημείων συμφόρησης και την αύξηση της συνολικής αποδοτικότητας της μεταποιητικής σας επιχείρησης

Η μεταποίηση είναι μια σύνθετη διαδικασία που περιλαμβάνει διάφορα στάδια και διαδικασίες. Από την προμήθεια πρώτων υλών έως την παράδοση τελικών προϊόντων, κάθε βήμα είναι κρίσιμο για την επιτυχία μιας μεταποιητικής επιχείρησης. Παρ' όλα αυτά, ακόμη και οι πιο βελτιστοποιημένες διαδικασίες μπορεί να αντιμετωπίζουν προκλήσεις και ένα από τα πιο συνηθισμένα προβλήματα είναι οι συμφορήσεις. Σε αυτόν τον οδηγό, θα συζητήσουμε τι είναι τα σημεία συμφόρησης, πώς να τα εντοπίσετε και, κυρίως, πώς να τα εξαλείψετε για να αυξήσετε τη συνολική αποδοτικότητα της μεταποιητικής σας επιχείρησης.

Ποιο είναι το σημείο συμφόρησης στη μεταποίηση;

Το σημείο συμφόρησης είναι ένα στάδιο σε μια παραγωγική διαδικασία όπου η παραγωγή επιβραδύνεται ή σταματά λόγω έλλειψης πόρων, όπως εργατικού δυναμικού, εξοπλισμού ή υλικών. Για παράδειγμα, αυτό μπορεί να συμβεί όταν ένα μηχάνημα ή ένας εργαζόμενος στην παραγωγική διαδικασία είναι πιο αργός ή λιγότερο αποδοτικός από τους άλλους. Ως αποτέλεσμα, τα άλλα μηχανήματα ή οι άλλοι εργαζόμενοι πρέπει να επιβραδύνουν ή να σταματήσουν για να περιμένουν το πιο αργό μηχάνημα ή τον πιο αργό εργαζόμενο να προλάβει.

Το στάδιο συμφόρησης περιορίζει τη συνολική ικανότητα της παραγωγικής διαδικασίας και μπορεί να προκαλέσει καθυστερήσεις, αυξημένο κόστος παραγωγής και χαμένες προθεσμίες. Συνεπώς, ο εντοπισμός και η αντιμετώπιση των σημείων συμφόρησης είναι ζωτικής σημασίας για τη διασφάλιση της ομαλής ροής της παραγωγής και τη μεγιστοποίηση της αποδοτικότητας της μεταποιητικής επιχείρησής σας.

Πώς να εντοπίσετε τα σημεία συμφόρησης στη διαδικασία παραγωγής σας

Αρχικά, ο εντοπισμός των σημείων συμφόρησης στη διαδικασία παραγωγής σας μπορεί να είναι δύσκολος, αλλά είναι απαραίτητος για τη μεγιστοποίηση της αποδοτικότητας και της παραγωγικότητας. Είναι το πρώτο βήμα προς την εξάλειψή τους. Μερικά κοινοί δείκτες που μπορούν να σας βοηθήσουν να τα εντοπίσετε είναι οι μεγάλοι χρόνοι αναμονής μεταξύ των διεργασιών, οι συχνές βλάβες μηχανών και τα προβλήματα συντήρησης, ή ακόμη και τα υψηλά επίπεδα απορριμμάτων και επανεπεξεργασίας. Ακολουθούν ορισμένα βήματα που μπορείτε να ακολουθήσετε για να εντοπίσετε αυτά τα σημεία συμφόρησης στην παραγωγική σας διαδικασία:

1. Αναλύστε τα δεδομένα παραγωγής σας: Συλλογή και ανάλυση δεδομένων σχετικά με τη διαδικασία παραγωγής για τον εντοπισμό προτύπων και τάσεων. Χρησιμοποιήστε εργαλεία όπως αισθητήρες μηχανών, συστήματα παρακολούθησης της παραγωγής και λογισμικό διαχείρισης ροής εργασιών για τη συλλογή δεδομένων και τον εντοπισμό σημείων συμφόρησης.

2. Χαρτογραφήστε τη διαδικασία παραγωγής σας: Δημιουργήστε μια οπτική αναπαράσταση της παραγωγικής σας διαδικασίας για να εντοπίσετε τα στάδια που προκαλούν καθυστερήσεις ή αναποτελεσματικότητα. Χρησιμοποιήστε διαγράμματα ροής διαδικασιών, χαρτογράφηση ροής αξίας ή άλλες τεχνικές οπτικοποίησης για να χαρτογραφήσετε τη διαδικασία παραγωγής σας.

3. Διεξαγωγή ανάλυσης χωρητικότητας: Καθορίστε τη μέγιστη δυναμικότητα κάθε σταδίου της παραγωγικής σας διαδικασίας και συγκρίνετε την με την πραγματική παραγωγή. Εντοπίστε τα στάδια που λειτουργούν κάτω από τη δυναμικότητα και διερευνήστε τη βασική αιτία

Πώς να εξαλείψετε τα σημεία συμφόρησης στη διαδικασία παραγωγής σας

Η εξάλειψη των σημείων συμφόρησης είναι ζωτικής σημασίας για την αύξηση της αποδοτικότητας της παραγωγικής σας διαδικασίας. Ακολουθούν ορισμένες στρατηγικές που πρέπει να εξετάσετε:

1. Επανασχεδιασμός της διαδικασίας παραγωγής: Μετά τον εντοπισμό των σημείων συμφόρησης, εξετάστε το ενδεχόμενο επανασχεδιασμού της παραγωγικής διαδικασίας για την εξάλειψη του σταδίου συμφόρησης. Αυτό θα μπορούσε να περιλαμβάνει την αναδιάταξη της γραμμής παραγωγής, την αύξηση της χωρητικότητας του εξοπλισμού ή την πρόσληψη πρόσθετου προσωπικού.

2. Εφαρμογή αυτοματισμού: Η αυτοματοποίηση επαναλαμβανόμενων ή χειροκίνητων εργασιών μπορεί να συμβάλει στη μείωση των σημείων συμφόρησης και στην αύξηση της αποδοτικότητας της παραγωγής. Εξετάστε το ενδεχόμενο εφαρμογής ρομποτικής, μηχανικής μάθησης ή άλλων τεχνολογιών αυτοματισμού για να βελτιώσετε την αποτελεσματικότητα της παραγωγικής σας διαδικασίας.

3. Εκπαιδεύστε τους υπαλλήλους: Παροχή κατάρτισης και υποστήριξης στους εργαζομένους για τη βελτίωση των δεξιοτήτων τους και την αύξηση της παραγωγικότητάς τους. Αυτό μπορεί να συμβάλει στη μείωση των σημείων συμφόρησης που προκαλούνται από ανθρώπινα λάθη ή αναποτελεσματικότητα

Πώς μπορεί να βοηθήσει η Epoptia

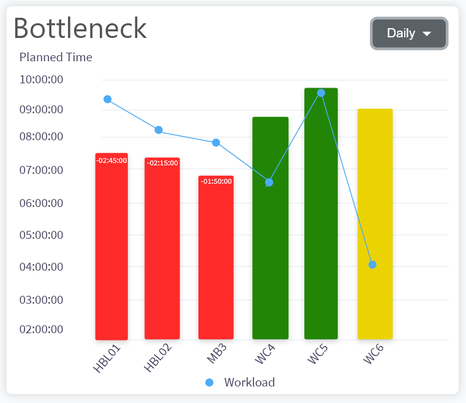

Το Epoptia είναι ένα ισχυρό σύστημα εκτέλεσης παραγωγής που βασίζεται στο cloud και προσφέρει δυνατότητες παρακολούθησης και υποβολής εκθέσεων σε πραγματικό χρόνο. Αυτό βοηθά τους κατασκευαστές να εντοπίζουν και να εξαλείφουν γρήγορα τα σημεία συμφόρησης στη διαδικασία παραγωγής τους. Με την προηγμένη τεχνολογία του, μπορεί να συλλέγει και να αναλύει δεδομένα παραγωγής, να χαρτογραφεί τη διαδικασία παραγωγής και να διεξάγει ανάλυση χωρητικότητας για τον εντοπισμό περιοχών που προκαλούν καθυστερήσεις ή αναποτελεσματικότητα.

Η Epoptia μπορεί να σας βοηθήσει να επανασχεδιάσετε τη διαδικασία παραγωγής σας, να αυτοματοποιήσετε επαναλαμβανόμενες ή χειροκίνητες εργασίες και να εκπαιδεύσετε τους υπαλλήλους σας για να βελτιώσουν τις δεξιότητές τους και να αυξήσουν την παραγωγικότητά τους. Το παρακολούθηση σε πραγματικό χρόνο και τα χαρακτηριστικά αναφοράς σας επιτρέπουν να λαμβάνετε γρήγορα τεκμηριωμένες αποφάσεις. Με αυτόν τον τρόπο, μπορείτε να βελτιστοποιήσετε τη διαδικασία παραγωγής σας και να αυξήσετε τη συνολική αποδοτικότητα της μεταποιητικής επιχείρησής σας.

Αυτό που κάνει το Epoptia να ξεχωρίζει είναι η ικανότητά του να παρέχει πολύτιμες πληροφορίες για τις διαδικασίες παραγωγής σας. Αυτό σας βοηθά να λαμβάνετε τεκμηριωμένες αποφάσεις για τη βελτιστοποίηση της αποδοτικότητας. Με ένα ανοιγοκλείσιμο του ματιού, μπορείτε να έχετε πρόσβαση σε όλες τις πληροφορίες που χρειάζεστε. Με αυτόν τον τρόπο, μπορείτε να εντοπίσετε και να εξαλείψετε τα σημεία συμφόρησης, βελτιώνοντας τελικά τη διαδικασία παραγωγής σας και αυξάνοντας το τελικό σας αποτέλεσμα.

Εάν αντιμετωπίζετε προβλήματα συμφόρησης στην παραγωγική σας διαδικασία και αναζητάτε μια λύση για τη βελτιστοποίηση της αποδοτικότητας, επικοινωνήστε μαζί μας σήμερα για να προγραμματίσετε μια παρουσίαση.

Για περισσότερες πληροφορίες, δείτε https://bit.ly/3vYnb4f.